Basic Info.

Model NO.

PBZ400P

Object

Hemp

Separation Mode

Filter Type

Operating Type

Intermittent Type

Installation

Vertical

Centrifuge Type

Alcohol Extraction Centrifuge

Pressure

Medium Pressure

Condition

New

Operation

Manual Batch Operation

Machine Control

PLC Control

Centrifugal Type

Screen Centrifuge

Screen Touch

Opotional

Discharge

Top Discharge

Braking System

Dynamic Braking

Speed Control

Frequency Inverter

Application

Alcohol Extraction Centrifuge

Jacketed

Yes

Flooded

Yes

Transport Package

Poly Film and Wood Carton Packing

Trademark

Huada

Origin

China

HS Code

8421199090

Production Capacity

100 Sets/Month

Packaging & Delivery

Package Size

1500.00cm * 1500.00cm * 1500.00cm

Package Gross Weight

1500.000kg

Product Description

Pharmaceutical centrifuge

Alcohol Extraction Centrifuge is immersed Manual Top Discharge Filter Centrifuge; it features as simple structure, reliable performance, easy operation and maintenance, flexible control time, skimming thickness according to material property.

The material is fed into the basket through the feeding pipe on the hermetic closure casing; under the action of the centrifuge force, the liquid-phase passes through the filter medium and the discharged out of the machine, while the solid-phase material is retained inside the basket and, after the machine is stopped, the material is discharged from the top. The centrifuge has such features as smooth running, easy & convenient operation as well as conducting feeding, washing and dehydrating under the state of hermetic closure, etc.

Working Steps

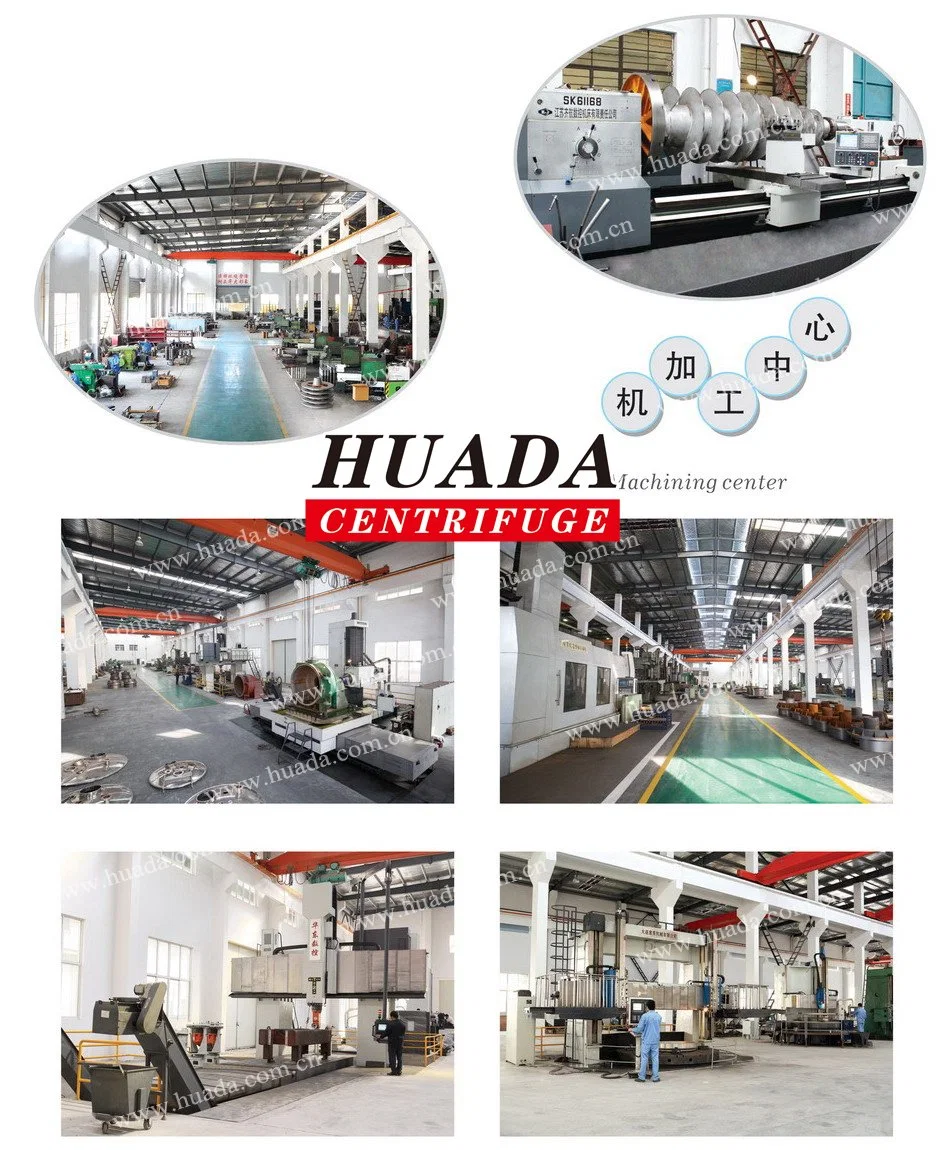

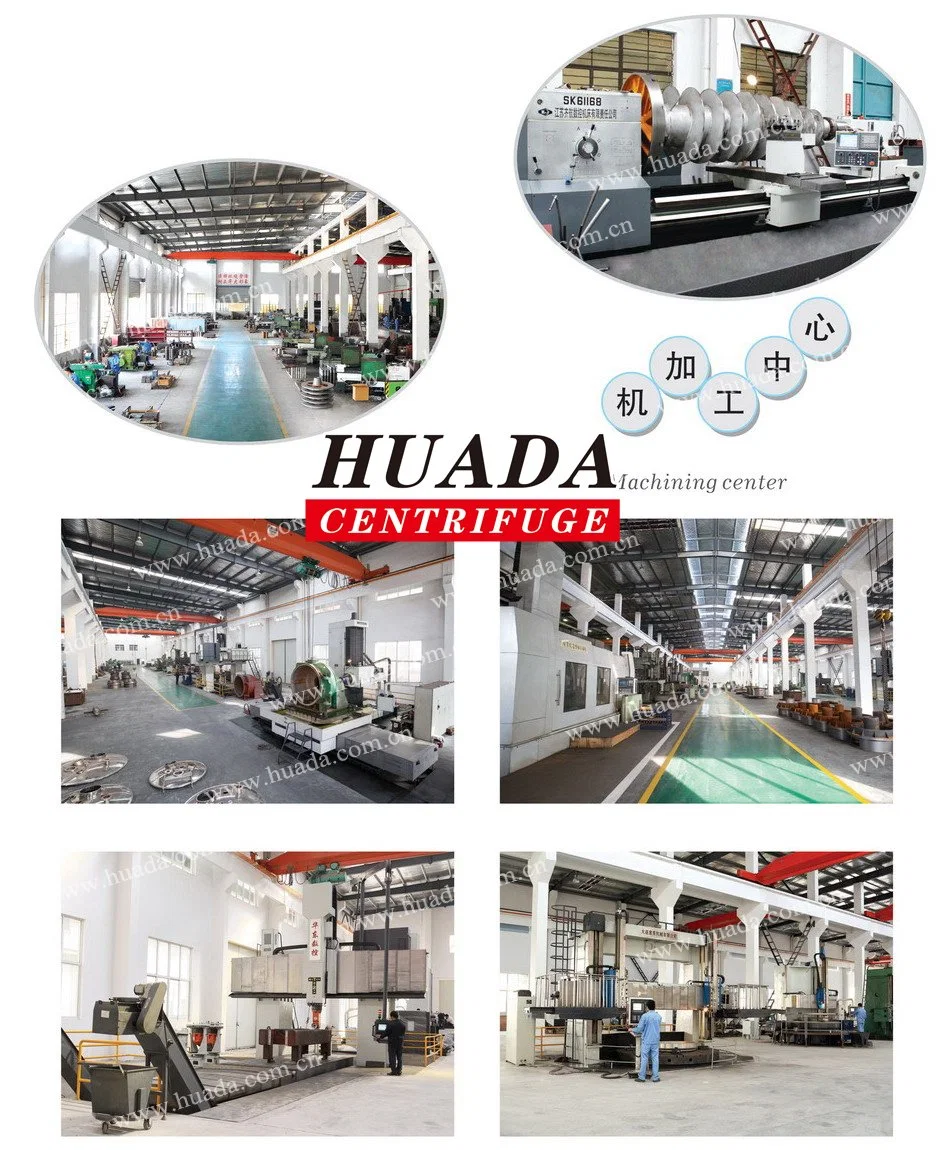

Production site

Product Description

Alcohol Extraction Centrifuge is immersed Manual Top Discharge Filter Centrifuge; it features as simple structure, reliable performance, easy operation and maintenance, flexible control time, skimming thickness according to material property.

The material is fed into the basket through the feeding pipe on the hermetic closure casing; under the action of the centrifuge force, the liquid-phase passes through the filter medium and the discharged out of the machine, while the solid-phase material is retained inside the basket and, after the machine is stopped, the material is discharged from the top. The centrifuge has such features as smooth running, easy & convenient operation as well as conducting feeding, washing and dehydrating under the state of hermetic closure, etc.

Main Technical Parameters

| Model | Basket Diameter (MM) | Flooded Volume (L) | Dry hemp (Ibs) | Motor Power (KW) |

| PBZ330P | 330 | 50 | 10-15 | 1.5 |

| PBZ400P | 400 | 100 | 25-30 | 2.2 |

| PSB600P | 600 | 200 | 50-55 | 5.5 |

Standard Features

- Closed-Loop System

- 304 and 316L Sanitary Stainless-Steel Construction

- Jacket Insulation

- Easy Material Loading/ Unloading

- Bi-Directional Agitation

- Auto/Manual Controls

- Digital HMI Interface

- Variable Speed Control

- Easy Material Loading/ Unloading

- Heavy-Duty Spin Drying

- Technical Support

Extraction Cycles

- Huada Alcohol extraction centrifuge offers 3 Program cycles: 1. Spray wash; 2. Agitation wash; 3. Spin dry cycle.

- Operator fills filter bag with milled plant material and places it in the machine.

- The centrifuge is then flooded, and bi-directional agitated for full target compound

removal. - After the wash, the plant material undergoes a medium duty spin dry till high speed

spin dry to remove the liquid as much as possible. - The alcohol wash is then collected to a tank for further processing

Working Steps

- System loading: A pre-loaded closed filter bag is placed into the basket and the system is sealed to begin the cycle.

- Program Menu: The 'Spray Wash' or 'Agitation Wash' program is selected on the program manu where the RPM and cycle times are set to the operator's specifications.

- Alcohol Fill: Alcohol is pumped from source tank into the centrifuge via an inlet valve or spray nozzle.

- The Wash cycle: The plant material undergoes either a spray wash or an agitated wash with a set number of bi-directional agitations.

- System Draining: When the wash cycle is complete, the outlet valve is manually

opened and the liquid drained. The alcohol wash is pumped to a properly rated storage

tank for further processing. - Spin Dry Cycle: The 'Spin Dry' program is selected on the program and the drying cycle is started. The wet plant solids are spun dry of the remaining alcohol mixture within.

- System Unloading: when the dry cycle is complete, centrifuge is unloaded by taking the filter bag out from the basket.

- Repeat Process.

Production site